Why Buy a Bandit Hand-Fed Chipper?

Bandit hand-fed wood chippers have been manufactured since 1983 and are known for their performance, reliability, efficiency, and durability. They retain one of the highest resale values on the market and are the preferred choice by a variety of tree care professionals. The Bandit hand-fed product line is the most diverse line of models configured to serve various applications. Multiple disc and drum style tow-behind models ranging from 6 inches to 21 inches capacity can be chosen. Select models are also available as self-propelled with a rubber or steel track undercarriage. The Model 90XP can also be ordered as a chipper/chip box combo unit, and the 21XP can be equipped with a Kesla loader.

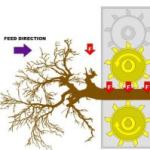

The heart of each Bandit chipper is the slide box feed system. This design is what founder Mike Morey, Sr. introduced on the very first chipper in 1983 and is still utilized on most Bandit chippers produced today. This slide box allows the top feed wheel to travel straight up and down with the flow and diameter of material passing through the feed system. This system applies direct down pressure, easily crushing material through the spring tensioning system or the hydraulic lift cylinder, making the chipper easier to feed and reducing the need to re-position or trim material.

Most Bandit chippers offered feature powerful hydraulic dual feed wheels (a few models have a single feed wheel). Each feed wheel is powered by high-displacement hydraulic motors that pull material into the chipper. A bottom clean-out door is also included on dual feed wheel systems and extends knife life by allowing dirt and other debris to fall out. This clean-out door must be cleaned out periodically throughout the day.

All Bandit chippers feature a wide profile and heavy-duty infeed hoppers. Each hopper is standard with a 30-inch fold-down infeed tray that slopes 3 degrees, making the chipper easier to feed. In place of a folding infeed pan, a solid infeed with a heavy-duty rim is optional on 12-inch chippers and above.

Minimal electronic components and sensors are used on Bandit chippers. Most auxiliary functions are controlled by hydraulics, simplifying maintenance while reducing downtime.

Each Bandit chipper is designed to be easy to work on and maintain. Component covers can easily be removed, allowing easy access to items needing maintenance. Hydraulic hoses are easily accessible to see if there are leaks or loose fittings. All grease points and filters are also easily accessed, and engines with enclosures feature removable panels, allowing easy access to the engine.

Most major engine manufacturers have a wide array of gas and diesel engine options. Engines available include:

- Gasoline: Briggs, Kohler, Ford, and PSI

- Diesel: Caterpillar, Cummins, John Deere, and Kohler

Depending on the model, Bandit drum-style chippers feature larger diameter drums with more knives compared to some competitive units (usually in the 12” to 15” range). The larger Bandit drums turn slower, generating more torque requiring less fuel and horsepower to chip material. With more knives, more cuts per revolution create a smoother, more efficient chipping action with reduced vibration.

Each Bandit chipper is designed to throw chips at a high velocity. Cupped blades are mounted to the disc on the disc-style chippers, capturing and throwing material up through the disc housing. Drum-style chippers feature numerous fan blades mounted to each side of the drum that assist with chip discharging. Adjustable side vents and covers can be adjusted or removed for additional throwing action. The drum-style chippers also feature a slot mounted on the back side of the drum transition. This slot is known as the “Power Slot” and creates more airflow and reduces the time needed to clean out the housing and discharge in the rare event the machine plugs with chips.

Due to the heavy-duty construction of the disc/drum and feed system, the Bandit fabricated a 5-year “GUTS” warranty covering components.

Bandit chippers comply with all OSHA and ANSI safety requirements and offer additional safety features that go above and beyond industry standards.

Learn more about the safety features of a Bandit hand-fed chipper!

Check out how a Bandit chipper is manufactured!

If you have additional questions on how a Bandit chipper will make your business more efficient, call Bandit or a local authorized dealer today. We are always happy to show how a Bandit chipper will make a difference!